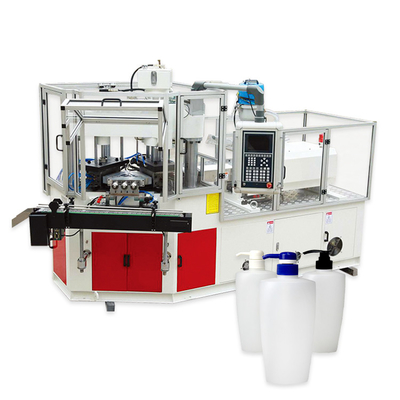

Oil-electric hybrid high-speed preform injection molding machine.Special injection molding machine for fast preform.The whole machine adopts the design style of European style, and the appearance is beautiful and high-end.

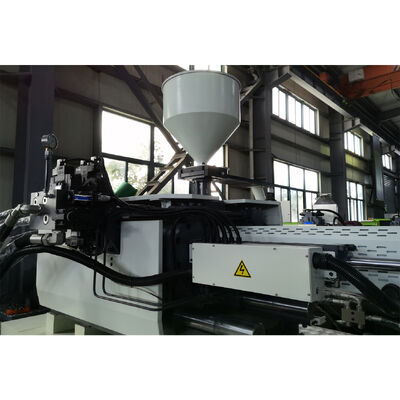

The safety door glass is made of PC board material, which has good strength and high transparency, while most of the injection molding machines in the same industry use acrylic board, which has poor strength, vulnerable parts, and poor transparency.

The blanking plate is heightened with two water pipe perforations, which is convenient for connecting the water inlet and outlet pipes

of the mould.

For models above 320 tons, the base of the pallet is lengthened to allow the weight of the reducer to be distributed on the base.

Otherwise, the reducer of a large preform machine is heavy and the weight is distributed on the drive shaft, which is easy to

deform and break. (Exclusive design of EFFICENT type)

deform and break. (Exclusive design of EFFICENT type)